|

Elevator Belt

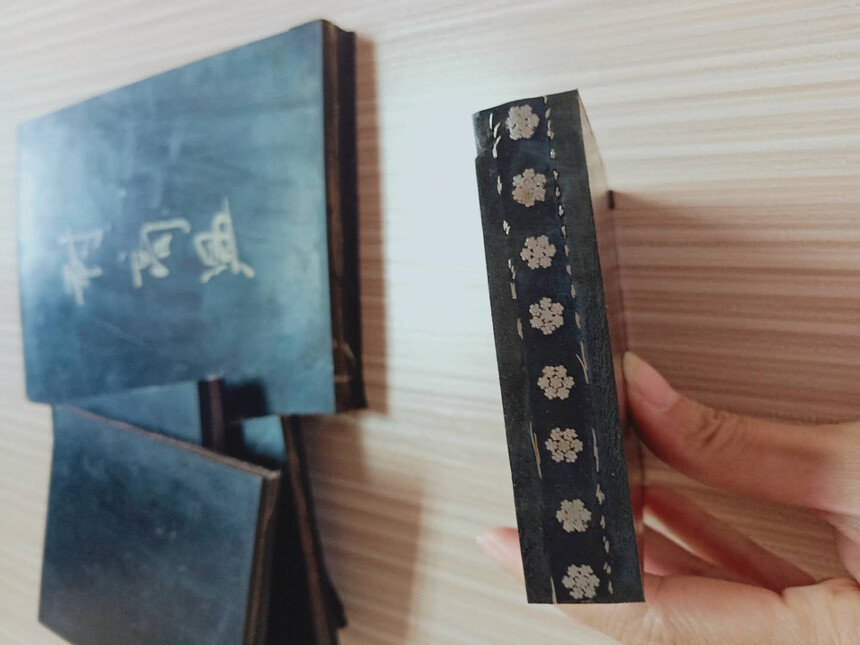

Company's main product - steel cord elevator belt, which is differentiated according to the longitudinal tensile strength, width and covering layer performance; the strength specification is expressed by the nominal value of ST and longitudinal tensile strength n / mm; the width specification is expressed in mm; the covering glue performance is expressed in MPa; the steel wire rope core of the steel wire rope lifting belt is galvanized to ensure the safety of the steel wire Anti rust and anti erosion of rope. The adhesive in the middle is pure natural rubber with high strength adhesion value to ensure the firm contact with the steel wire rope, and the covering rubber is high abrasion styrene butadiene rubber to ensure the fatigue resistance of the belt. The company can customize all kinds of non-standard lifting belts according to customer's requirements, and the drilling will not damage the steel wire rope core. The company's products use double-layer closely arranged steel wire meridian, with a longitudinal distance of 1.5mm/piece, which has a great advantage in controlling the damage of the bucket and materials to the belt in the process of bucket elevator lifting, and has a good anti tearing effect.

LastSteel Cord BeltNextSidewall Belt |